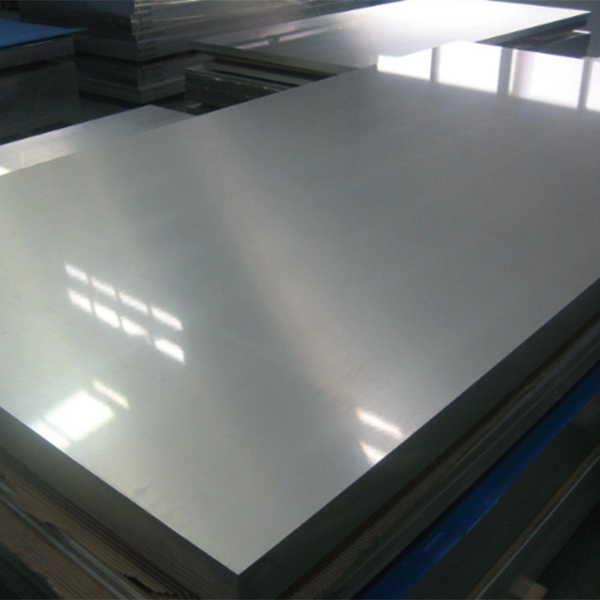

Customized 304 304L Ipleyiti Steel Steel

Iimpawu zepleyiti yensimbi engenasici

1. Ukuweldability

Ukusetyenziswa kweemveliso ezahlukeneyo kuneemfuno ezahlukeneyo zokusebenza kwe-welding.Iklasi ye-tableware ngokubanzi ayifuni ukusebenza kwe-welding, kwaye iquka amanye amashishini eembiza.Nangona kunjalo, uninzi lweemveliso zifuna ukusebenza kakuhle kwe-welding yezinto ezikrwada, ezinje nge-tableware yodidi lwesibini, iikomityi ze-thermos, imibhobho yentsimbi, izifudumezi zamanzi, izixhobo zokuhambisa amanzi, njl.

2. Ukumelana nokubola

Uninzi lweemveliso zensimbi ezingenasici zifuna ukuxhathisa okulungileyo kwe-corrosion, njenge-Class I kunye ne-II tableware, izitya zasekhitshini, izifudumezi zamanzi, i-dispensers yamanzi, njl. kwaye ugalele emva kwethuba elithile.Susa isisombululo, uhlambe kwaye usomise, kwaye ulinganise ukulahlekelwa kwesisindo ukumisela iqondo lokubola (Qaphela: Xa umkhiqizo uphothiweyo, umxholo we-Fe kwi-cloth abrasive or sandpaper uya kubangela amabala e-rust ebusweni ngexesha lovavanyo).

3. Ukusebenza kakuhle

Kuluntu lwanamhlanje, iimveliso zensimbi ezingenasici zilungiswa ngokubanzi ngexesha lemveliso, kwaye kuphela iimveliso ezimbalwa ezifana nezifudumezi zamanzi kunye ne-liner ye-dispenser yamanzi ayifuni ukupolishwa.Ke ngoko, oku kufuna ukuba ukusebenza kokupholisha kwezinto ezikrwada kulunge kakhulu.Imiba ephambili echaphazela ukusebenza kokupholisha zezi zilandelayo:

(1) iziphene kumphezulu wemathiriyeli ekrwada.Njengemikrwelo, i-pitting, pickling, njl.

(2)Ingxaki yemathiriyeli ekrwada.Ukuba ubunzima buphantsi kakhulu, akuyi kuba lula ukupolisha xa upholisha (ipropati ye-BQ ayilungile), kwaye ukuba ubunzima buphantsi kakhulu, i-penomenon ye-orange peel ilula ukubonakala phezu komhlaba ngexesha lokudweba okunzulu, ngaloo ndlela ichaphazela. ipropati ye-BQ.Iimpawu ze-BQ ezinobunzima obuphezulu zilungile.

(3) Kwimveliso enzulu, amabala amancinci amnyama kunye ne-RIDGING iya kubonakala phezu kwendawo kunye nenani elikhulu lokuguqulwa, ngaloo ndlela ichaphazela ukusebenza kwe-BQ.

4. Ukumelana nobushushu

Ukumelana nobushushu kuthetha ukuba insimbi engenasici isenako ukugcina iimpawu zayo ezibalaseleyo zomzimba nezomatshini kumaqondo obushushu aphezulu.

Impembelelo yekhabhoni: Ikhabhoni yenziwe ngamandla kwaye izinzile kwiintsimbi ezingenasici ze-austenitic.Izinto ezimisela i-austenite kunye nokwandisa ummandla we-austenite.Ikhono lekhabhoni ukwenza i-austenite malunga namaxesha angama-30 e-nickel, kunye nekhabhoni yinto ye-interstitial enokunyusa kakhulu amandla e-austenitic stainless steel ngokuqiniswa kwesisombululo esiqinileyo.Ikhabhoni inokuphucula uxinzelelo lwe-corrosion resistance ye-austenitic stainless steel kwi-chloride egxininiswe kakhulu (njenge-42% ye-MgCl2 isisombululo esibilisayo).

Nangona kunjalo, kwi-austenitic steel stainless steel, ikhabhoni ihlala ithathwa njengento eyingozi, ngakumbi ngenxa yokuba phantsi kweemeko ezithile (ezifana ne-welding okanye ukufudumeza kwi-450 ~ 850 ° C) kwi-corrosion resistance yensimbi engenasici, ikhabhoni inokusebenzisana nekhabhoni intsimbi.I-Chromium yenza i-chromium ephezulu ye-Cr23C6-uhlobo lwe-carbon compounds, olukhokelela ekuphelelweni kwe-chromium yendawo, enciphisa ukunyanzeliswa kwe-corrosion yensimbi, ngakumbi ukuchasana ne-intergranular corrosion.ke ngoko.Uninzi lwezintsimbi ze-chromium-nickel austenitic ezisanda kuphuhliswa ukususela ngo-1960 ziindidi zekhabhoni eziphantsi kwe-ultra-low kunye nomxholo wekhabhoni ongaphantsi kwe-0.03% okanye i-0.02%.Iyakwazi ukwaziwa ukuba njengoko umxholo wekhabhoni uyancipha, i-intergranular corrosion susceptibility yensimbi iyancipha.Xa umxholo wekhabhoni ungaphantsi kwe-0.02% unesiphumo esicacileyo, kwaye ezinye iimvavanyo zibonise ukuba ikhabhoni iphinda ikhulise ukuthambekela kwe-pitting corrosion ye-chromium austenitic stainless steel.Ngenxa yempembelelo eyingozi yekhabhoni, akusiyo kuphela umxholo wekhabhoni omele ulawulwe uphantsi kangangoko kunokwenzeka kwinkqubo yokunyibilikisa i-austenitic stainless steel, kodwa nakwinkqubo elandelayo yokusebenza okushushu, okubandayo kunye nobushushu bokuthintela ukwanda kwekhabhoni. umphezulu wensimbi engenasici kwaye uphephe i-chromium carbides Precipitate.

5. Ukumelana nokubola

Xa isixa see-athom zechromium kwintsimbi singekho ngaphantsi kwe-12.5%, amandla e-electrode entsimbi anokutshintshwa ngokukhawuleza asuke ekubeni angabikho amandla ukuya kwi-electrode encomekayo.Ukuthintela ukubola kwe-electrochemical.

Umgangatho wokwenziwa kwepleyiti yensimbi engenasici

Ipleyiti yensimbi engenasici inomgangatho ogudileyo, iplastiki ephezulu, ukuqina kunye namandla omatshini, kwaye iyamelana ne-corrosion ngama-acids, i-alkaline gases, izisombululo kunye nezinye imidiya.Yintsimbi engavuthwanga lula, kodwa ayinamhlwa kwaphela.Ipleyiti yensimbi engenasici ibhekisa kwipleyiti yentsimbi ekwaziyo ukumelana nokudleka yimithombo yeendaba ebuthathaka efana nomoya, umphunga kunye namanzi, ngelixa ipleyiti yentsimbi ekwaziyo ukumelana neasidi ibhekisa kwipleyiti yentsimbi ekwaziyo ukunyathela ngamajelo eendaba adlayo anjengeasidi, ialkali, kunye netyuwa.Ipleyiti yensimbi engenastainless ikhona ngaphezulu kwenkulungwane ukusukela oko yaphuma ekuqaleni kwenkulungwane yama-20.

Ipleyiti yentsimbi engatyiwa ligama eliqhelekileyo lepleyiti yentsimbi engatyiwayo kunye nepleyiti yentsimbi ekwaziyo ukumelana neasidi.Yaziswa ekuqaleni kwale nkulungwane, uphuhliso ipleyiti steel stainless uye wabeka izinto ezibalulekileyo kunye nesiseko zobugcisa kuphuhliso lweshishini mihla kunye nenkqubela phambili yenzululwazi kunye nobuchwepheshe.Kukho iintlobo ezininzi zeepleyiti zensimbi ezingenasici ezineempawu ezahlukeneyo.Kuye kwakheka iindidi ezininzi kwinkqubo yophuhliso.

Ngokwesakhiwo, yahlulwe yangamacandelo amane: i-austenitic stainless steel, i-martensitic stainless steel (kubandakanya i-precipitation hardening steel stainless), i-ferritic stainless steel, kunye ne-austenitic plus ferritic duplex steel stainless.Eyona khemikhali iphambili okanye ezinye izinto ezibonakalayo kwipleyiti yentsimbi zihlelwa kwipleyiti yensimbi engenasici, chromium nickel steel stainless plate, chromium nickel molybdenum steel stainless plate, carbon steel stainless plate, high molybdenum steel stainless plate, high quality steel stainless plate. , njl.

Ngokweempawu zokusebenza kunye nokusetyenziswa kweepleyiti zentsimbi, zohlulwe zibe ziipleyiti zentsimbi ezingevani ne-nitric acid-resistainless, i-sulfuric acid-resistant steel stainless plates, i-pitting-resistant steel stainless plates, iipleyiti zentsimbi ezikwaziyo ukumelana noxinzelelo, kunye nokuqina okuphezulu. iipleyiti zensimbi ezingenasici.Ngokweempawu ezisebenzayo zeplate yentsimbi, yahlulwe ibe yintsimbi ephantsi yobushushu obuphantsi, ipleyiti yentsimbi engenamagnetic, ipleyiti yentsimbi engenazibuthe, ipleyiti yensimbi engenasici, ipleyiti yensimbi engenasici, njl. kwiimpawu zesakhiwo seplate yensimbi, iimpawu zokwakheka kweekhemikhali zentsimbi yensimbi kunye nokudibanisa kwezi zibini.

Ngokubanzi yahlulwe ibe martensitic steel stainless, ferritic steel stainless, austenitic steel stainless, duplex steel stainless kunye precipitation lukhuni intsimbi, njl okanye zahlulwe zibe ziindidi ezimbini: chromium stainless steel kunye nickel steel stainless.Uluhlu olubanzi lokusetyenziswa Ukusetyenziswa okuqhelekileyo: i-pulp kunye nezixhobo zephepha zokutshintsha ubushushu, izixhobo zomatshini, izixhobo zokudaya, izixhobo zokulungisa ifilimu, iipayipi, izinto zangaphandle zezakhiwo kwiindawo ezinxweme, njl.

Ipleyiti yensimbi engenasici inomgangatho ogudileyo, iplastiki ephezulu, ukuqina kunye namandla omatshini, kwaye iyamelana ne-corrosion ngama-acids, i-alkaline gases, izisombululo kunye nezinye imidiya.Yintsimbi engavuthwanga lula, kodwa ayinamhlwa kwaphela.

Ubukhulu beenyawo kunye nobukhulu obuqhelekileyo bepleyiti yensimbi engenasici

Ubungqingqwa beenyawo buthetha ukuba ubungqingqwa benene abuhlukanga kakhulu kubukhulu bethiyori (ekwabizwa ngokuba bubungqingqwa beleyibhile), nto leyo ingumahluko omncinci ongalunganga.Ukuba ukutyeba kweleyibhile yi-1.0MM, ubukhulu benyawo obufunekayo buncinci malunga ne-0.98MM-1.0MM, kwaye ubukhulu beenyawo bunokuba buqondwa "njengobungqimba ngokwaneleyo", kwaye ubukhulu obuqhelekileyo bubunzima bethiyori.Iikhoyili zentsimbi zibhalwa xa ziphuma kumzi-mveliso, zibonisa ubuninzi bethiyori.Lo bubunzima obuqhelekileyo.