I-Titanium alloy TA1 ityhubhu ingasetyenziswa i

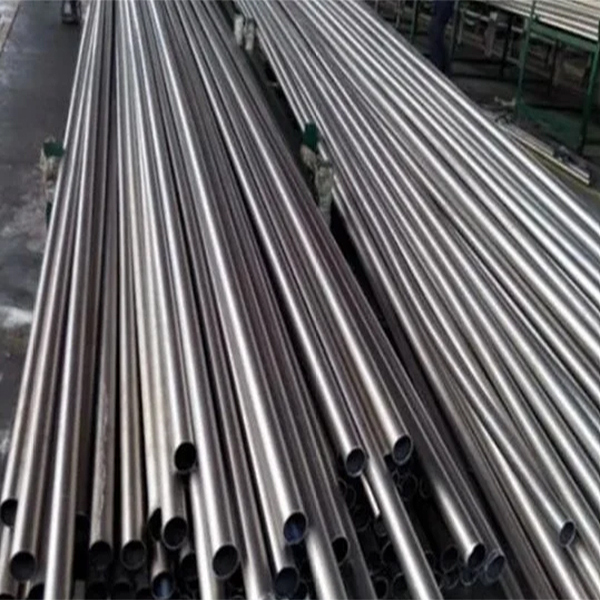

I-Titanium Alloy TA1 Tube, yenziwe nge-titanium alloy, enokwahlulwa ibe ziindidi ezintathu ngokwesakhiwo.(1 iAluminiyam kunye netoti zongezwa kwititanium. Ialuminiyam, ichromium, imolybdenum, ivanadium kunye nezinye izinto ezixutywayo zongezwa kwititanium. 3 Titanium enealuminiyam kunye nevanadium kunye nezinye izinto.)Zineempawu eziphezulu zoomatshini, iimpawu ezigqwesileyo zesitampu, kwaye zinokuba idityaniswe ngeendlela ezahlukeneyo, ukuwelda amandla adibeneyo anokufikelela kwi-90% yamandla entsimbi ye-matrix, kunye nokusebenza kakuhle.Ityhubhu ye-Titanium inokumelana ne-corrosion ephezulu kwi-chloride, i-sulfide kunye ne-ammonia.Ukumelana nomhlwa kwe-titanium emanzini olwandle kuphezulu kunolo lwe-aluminiyam ialloy, intsimbi engatyiwa kunye nesiseko se-nickel alloy.I-Titanium ikwanamandla okumelana nempembelelo yamanzi.

I-Titanium Alloy TA1 Tube, uMgangatho oFanelekayo

I-GB/T 3620.1-2016 imigangatho ye-Titanium kunye ne-titanium alloy kunye nokwakheka kweekhemikhali

I-GB / T 3624-2010 I-Titanium kunye ne-titanium alloy tube standard

Iityhubhu ze-Titanium kunye ne-titanium alloy for heat exchangers kunye ne-condensers

I-TA1, i-TA2 kunye ne-TA3 yi-titanium ecocekileyo ye-industrial, eneempawu eziphezulu zoomatshini, iipropati ezigqwesileyo zesitampu, kwaye zinokudityaniswa ngeendlela ezahlukeneyo.Amandla adibeneyo adibeneyo anokufikelela kwi-90% yamandla ensimbi ye-matrix, kunye nokusebenza kokusika kulungile.Ityhubhu ye-Titanium inokumelana ne-corrosion ephezulu kwi-chloride, i-sulfide kunye ne-ammonia.Ukumelana nomhlwa kwe-titanium emanzini olwandle kuphezulu kunolo lwe-aluminiyam ialloy, intsimbi engatyiwa kunye nesiseko se-nickel alloy.I-Titanium ikwanamandla okumelana nempembelelo yamanzi.

Isetyenziswa ekwenzeni iityhubhu zecondenser kumanzi olwandle angcolisekileyo, amanzi anezinto eziqinileyo ezixhonywe phezulu, kunye namazinga aphezulu okuhamba.

I-Titanium Alloy TA1 Tube, uHlelo

Ngokutsho histological

1. i-aluminiyamu kunye nezinto ze-tin zongezwa kwi-titanium.

2. Izinto ze-alloy ezifana ne-aluminium, i-chromium, i-molybdenum kunye ne-vanadium zongezwa kwi-titanium.

3. i-aluminium kunye ne-vanadium yongezwa kwi-titanium.

Ingxubevange ye-Titanium inamandla aphezulu kunye noxinzelelo oluphantsi, iipropathi ezilungileyo zoomatshini, ukuqina okuhle kunye nokumelana nokugqwala.Ukongeza: ukusebenza kwenkqubo ye-titanium alloy ayilunganga, kunzima ukusika.Kwinkqubo eshushu, kulula kakhulu ukufunxa ukungcola okufana nehydrogen, ioksijini, initrogen kunye nekhabhoni.Kukho ukunganyangeki kokunxiba, inkqubo yokuvelisa entsonkothileyo.

Ukwahlulwe ngezinto ezixubeneyo

I-alloy esekelwe kwi-titanium kunye nezinye izinto ezongeziweyo.Imveliso ye-titanium kwimizi-mveliso yaqala ngo-1948.Imveliso yonyaka ye-titanium alloy processing imathiriyeli ifikelele ngaphezu kweetoni ezingama-40,000, phantse iindidi ezingama-30 ze-titanium alloy.I-alloys ye-titanium esetyenziswa kakhulu yi-Ti-6Al-4V (TC4), i-Ti-5Al-2.5Sn (TA7) kunye ne-industrial titanium ecocekileyo (TA1, TA2 kunye ne-TA3).

Ngokutsho kwe-utility cent

Ingxubevange ye-Titanium inokohlulwa ibe yingxubevange yokumelana nobushushu, i-alloy enamandla amakhulu, i-corrosion resistant alloy (ti-molybdenum, i-ti-Palladium alloy, njl.), ingxubevange yobushushu obuphantsi kunye ne-alloy yomsebenzi okhethekileyo (i-ti-iron hydrogen yokugcina izinto kunye nememori ye-nickel ye-ti-nickel i-alloy), njl njl.

I-Titanium Alloy TA1 Tube, Sebenzisa

I-Titanium Alloy TA1 Tube, Isetyenziswa ikakhulu ukuvelisa iinxalenye zecompressor ye-injini yenqwelomoya, ilandelwa ziirokethi, imijukujelwa kunye neenxalenye zesakhiwo senqwelomoya enesantya esiphezulu.Phakathi kwiminyaka yee-1960, i-titanium kunye nengxubevange yayo yayisele isetyenziswe kushishino ngokubanzi ukwenza ii-electrode zeshishini lokuhlanjululwa kwe-electrolysis, iicondenser zezikhululo zombane, izifudumezi zokuhluza ioli kunye nokukhutshwa kwetyuwa emanzini olwandle, kunye nezixhobo zokulawula ungcoliseko.I-Titanium kunye ne-alloys yayo iye yaba luhlobo lwezixhobo zolwakhiwo ezinganyangekiyo kwi-corrosion.Ukongeza, ikwasetyenziselwa ukuvelisa izixhobo zokugcina i-hydrogen kunye nokubumba i-alloys yememori.

I-China yaqala ukufunda i-titanium kunye ne-titanium alloys ngo-1956.

Ukuqulunqwa kwemichiza

| IBanga | N | C | H | Fe | THE | Al | IN | Kulungile | Mo | In | Of | Amandla Okuqina (MPa) | Isivuno Amandla (MPa) | Ubude (%) |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | UBhal | 240 | 138 | amashumi amabini anesine |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | UBhal | 345 | 275 | 20 |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | UBhal | 450 | 380 | 18 |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | 550 | 483 | 15 | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | UBhal | 895 | 828 | 10 |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | UBhal | 345 | 275 | 20 |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | UBhal | 620 | 70 | 15 |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 02-0.4 | 0.6-0.9 | UBhal | 438 | 345 | 18 |

| Uhlobo | Sinokubonelela nge-TB3, TB6, TC4, TC6, TC11, TC17,TC18 ngokweemfuno zakho. | |||||||||||||

| Umgangatho | ASTM B348, ASTM F67, ASTM F136, ISO5832-2, ISO5832-3, AMS 4928, AMS 4930, ASTM F1295, ASTM F1713, MIL-T-9047 | |||||||||||||

| Isicelo | I-Metallurgy, i-electronics, unyango, ikhemikhali, i-petroleum, i-pharmaceutical, i-aerospace, njl. | |||||||||||||

Umboniso weMveliso