TA2 titanium alloy ityhubhu yokusetyenziswa kushishino

I-TA2 ye-Titanium Alloy Pipe, i-Advantages

I-TA2 i-Titanium Alloy Pipe, xa ithelekiswa nezinye izinto zentsimbi, inezi zibonelelo zilandelayo:

1. Amandla athile aphezulu (amandla obunzima / ubuninzi) (jonga umzobo), amandla okuqina angafikelela kwi-100 ~ 140kgf / mm2, ngelixa ubuninzi bungama-60% kuphela ensimbi.

2. Amandla obushushu aphakathi alungile, ubushushu bokusetyenziswa bungamakhulu aliqela degrees ngaphezulu kune-alloy ye-aluminium, kwiqondo lobushushu eliphakathi kusenokugcina amandla afunekayo, anokusebenza kwi-450 ~ 500℃ lobushushu ixesha elide.

3. Ukumelana ne-corrosion elungileyo, umphezulu we-titanium emoyeni ngokukhawuleza wenza umaleko wefilimu efanayo kunye ne-oxide eshinyeneyo, inamandla okuxhathisa ukhukuliseko lweendaba ezahlukeneyo.I-Titanium ngokubanzi inokumelana ne-corrosion elungileyo kwi-oxidizing kunye nemidiya engathathi hlangothi, ngakumbi emanzini olwandle, i-chlorine emanzi kunye nezisombululo zekloridi.Kodwa ekunciphiseni okuphakathi, okufana nesisombululo se-hydrochloric acid, ukumelana ne-titanium corrosion kubi.

4. Ii-alloys ze-Titanium kunye nokusebenza kakuhle kweqondo lokushisa eliphantsi kunye nezinto eziphantsi kakhulu zokucima, ezifana ne-TA7, zinokugcina iplastiki ethile kwi--253℃.

5. Imodyuli e-elastic ephantsi, i-conductivity encinci ye-thermal, akukho ferromagnetism.

6. Ubunzima obuphezulu.

7. Ipropathi engafanelekanga yokupakisha kunye ne-thermoplasticity enhle.

Unyango olushushu lwe-Titanium alloy lunokufumana ukubunjwa kwesigaba esahlukileyo kunye ne-microstructure ngokulungelelanisa inkqubo yonyango lokushisa.Ngokuqhelekileyo kuqwalaselwa ukuba i-fine equiaxed microstructure ineplastiki efanelekileyo, ukuzinza kwe-thermal kunye namandla okudinwa.Ulwakhiwo lwe-acicular lunamandla ahlala ixesha elide, amandla okurhubuluza kunye nokuqina kokwaphuka.Izakhiwo ezixubeneyo kunye ne-acicular zineempawu ezingcono ezibanzi.

I-TA2 i-Titanium Alloy Pipe, Iindlela ezisetyenziswa ngokuqhelekileyo zonyango lobushushu zi-annealing, isisombululo kunye nonyango lokuguga.I-Annealing kukuphelisa uxinzelelo lwangaphakathi, ukuphucula iplastiki kunye nokuzinza kwe-microstructure, ukuze ufumane iipropati ezibanzi ezingcono.Ngokubanzi, iqondo lobushushu le-annealing ye-alloy ye-α kunye ne-(α+β) ingxubevange yi-120 ~ 200℃ ngaphantsi kwendawo yenguqu ye-(α+β) -- → isigaba se-β.Isisombululo kunye nonyango lokuguga kukufumana isigaba se-α ' kunye nesigaba se-metastable β se-martensite ngokupholisa ngokukhawuleza kwindawo yobushushu obuphezulu, kwaye emva koko ubole ezi zigaba ze-metastable ngokubamba kwindawo yobushushu obuphakathi, kwaye ufumane i-fine dispersed nqanaba lesibini. , njengesigaba se-α okanye i-compound, ukufezekisa injongo yokuqinisa i-alloy.Ngesiqhelo (alpha + beta) ingxubevange yokucima kwi-alpha + beta) -- - > indawo yenguqu yesigaba se-beta ngaphantsi kwe-40 ~ 100 ℃, i-metastable beta alloy quenching kwi-alpha + beta) -- - > indawo yenguqu ye-beta ngaphezu kwe-40 ~ 80 ℃.Ubushushu bokwaluphala ngokuqhelekileyo ngama-450 ~ 550℃.Ukongeza, ukuze kuhlangatyezwane neemfuno ezikhethekileyo ze-workpiece, ishishini likwasebenzisa i-double annealing, i-isothermal annealing, i-β yonyango lokushisa, unyango lwe-deformation yokushisa kunye nenye inkqubo yokunyanga ukushisa kwetsimbi.

I-TA2 ye-Titanium Alloy Pipe, uHlelo

Umbhobho we-titanium, umbhobho we-titanium welding, i-titanium splicing tee, i-titanium splicing elbow, i-titanium welding ring, ukunciphisa i-titanium, i-titanium tee, i-titanium elbow, i-titanium chimney, njl.

TA2 Titanium Alloy Pipe, Umgaqo wokuSebenza we

I-TA2 Titanium Alloy Pipe, Ikakhulu idibanisa zonke iintlobo zombhobho wesixhobo se-titanium, ezisetyenziselwa ukujikeleziswa kwezinto phakathi kwazo zonke iintlobo zezixhobo, umbhobho unokumelana nokugqwala kwezinto ze-titanium ngokwayo, ukuze kubuyiselwe umbhobho oqhelekileyo wombhobho oqhelekileyo awukwazi ukuhlangabezana nemfuno. .Ngokubanzi i-ф 108 ngasentla yimibhobho edityanisiweyo.

IiParameters eziphambili zobuGcisa

| DN (mm) | Ukulinganisa idiamitha yangaphandle (mm) | Izinto eziphathekayo |

| 15 | 18 | TA2 |

| 20 | 25 | TA2 |

| 25 | 32 | TA2 |

| 32 | 38 | TA2 |

| 40 | 45 | TA2 |

| 50 | 57 | TA2 |

| 65 | 76 | TA2 |

| 80 | 89 | TA2 |

| 100 | 108 | TA2 |

| 125 | 133 | TA2 |

| 150 | 159 | TA2 |

| 200 | 219 | TA2 |

| 250 | 273 | TA2 |

| 300 | 325 | TA2 |

| 350 | 377 | TA2 |

| 400 | 426 | TA2 |

| 450 | 480 | TA2 |

| 500 | 530 | TA2 |

| 600 | 630 | TA2 |

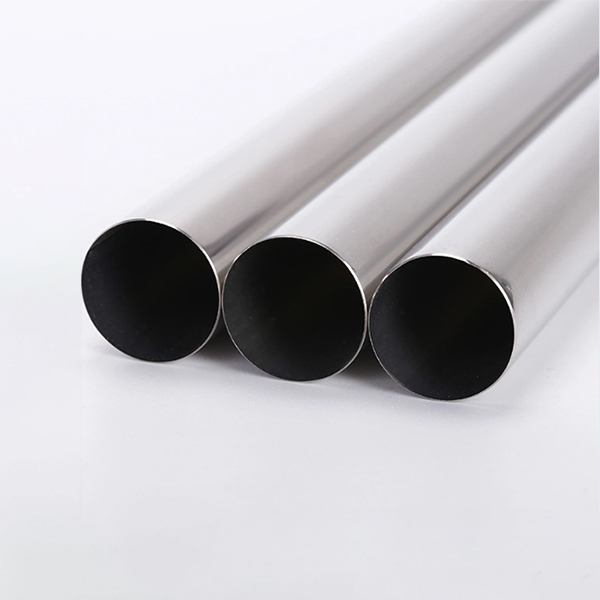

Umboniso weMveliso