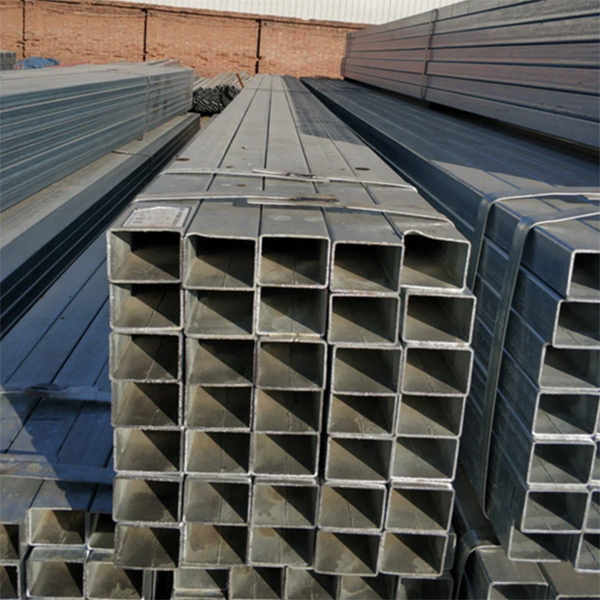

I-Square Structural Steel Tubing

Ityhubhu yentsimbi yolwakhiwo lwesikweri, ekwabizwa ngokuba ngumbhobho odityanisiweyo, yenziwe ngepleyiti yentsimbi okanye umcu emva kokwenza umbhobho odityanisiweyo wesikwere.

Isikwere se-sub yentsimbi, izixhobo ezisetyenziswa ngokuqhelekileyo zezi: Q235, Q235b, X42, X445, X44NI11, i-LORT19NI9, 0CR18NI11n, njalo.

Welded steel stainless umbhobho uhombiso (GB/T 18705-2002), welding steel stainless umbhobho for uhombiso isakhiwo (JG/T 3030-1995), welding wentsimbi umbhobho yokuthutha ulwelo oluphantsi-uxinzelelo (GB/T 3091-2001), kunye umbhobho wentsimbi odityanisiweyo wokutshintsha ubushushu (YB4103-2000).

Inkqubo yeMveliso

Ityhubhu yentsimbi yolwakhiwo yesikwere, izikhewu eziMxinwa zingasetyenziselwa ukuvelisa imibhobho edityanisiweyo enobubanzi obukhulu, kwaye izikhewu ezinobubanzi obufanayo zingasetyenziselwa ukuvelisa imibhobho edityanisiweyo enobubanzi obuhlukeneyo.Kodwa xa kuthelekiswa nobude obufanayo bombhobho wesquare othe tye, ubude be-weld bunyuka nge-30 ~ 100%, kwaye isantya sokuvelisa sisezantsi.

Ityhubhu yentsimbi yolwakhiwo enkulu okanye engqindilili, Ngokubanzi yenziwe ngentsimbi yentsimbi ngokuthe ngqo, kunye nombhobho omncinci odityanisiweyo obhityileyo umbhobho odityanisiweyo kufuneka udityaniswe ngokuthe ngqo ngebhanti yentsimbi.Emva kokupholisa okulula, ucingo lulungile.Ke ngoko, umbhobho odityanisiweyo omncinci ubukhulu becala usebenzisa ukuwelda komthungo othe tye, umbhobho odityanisiweyo omkhulu ubukhulu becala usebenzisa i-spiral welding.

Ubume uMsebenzi

square structural steel tubing, Ligama lombhobho osisikwere, ongumbhobho onobude obufanayo macala omabini.Yenziwe ngentsimbi ye-strip ngokusebenzisa isisombululo senkqubo kunye nokuqengqeleka.Ngokuqhelekileyo, i-strip ayipakishwanga, i-flat, i-crimped, idityaniswe kwityhubhu ejikelezayo, kwaye emva koko ijikelezwe ngumbhobho ojikelezayo we-Q215 we-weld square tube kwaye unqumle ubude bemfuno.Inani eliqhelekileyo ngama-50 ngepakethi nganye.Amandla abhekisela kumsebenzi wokuchasana nomonakalo (i-deformation yeplastiki efanelekileyo okanye i-fracture) ye-Q215 i-welded square data data yepayipi phantsi komthwalo we-static.Ngenxa yomthwalo wefom ye-tensile, i-contraction, i-winging, i-chear kunye nezinye iindlela, ngenxa yokuba amandla ahlula-hlulwa abe ngamandla, amandla oxinzelelo, amandla okugoba, amandla okucheba njalo njalo.Zonke iintlobo zamandla zihlala zinonxibelelwano oluqinisekileyo, ukusetyenziswa okuqhelekileyo kwamandla okuqina njengeyona naliti yamandla isisiseko.Amandla okumelana nokutshatyalaliswa kubizwa ngokuba bubulukhuni bentlawulo.

Umthwalo kwiindawo ezinenkqubela phambili enkulu ibizwa ngokuba yi-charge array load.Amandla, iplastiki kunye ne-Angle exoxwe ngasemva kombhobho we-square wentlawulo ye-array yokuqina phantsi kwesenzo somthwalo wentlawulo yentsimbi yonke imilinganiselo yokusebenza komatshini phantsi kwesenzo somthwalo we-static we-Q215 welded square pipe.Enyanisweni, oomatshini abaninzi baphantsi komthwalo ophindaphindiweyo wokuqeshwa, phantsi kwesi simo sonke ithuba lokukhathala.Ukukhathala kweAngle kukulinganisa idatha yesinyithi ethambileyo kunye nenqanaba elinzima lenaliti.Eyona ndlela inqabileyo yokulungisa i-Angle yangaphakathi kubomi bangoku yindlela yoxinzelelo ye-Angle, leyo kukusebenzisa inani elithile leyiphi imilo yentloko yoxinzelelo phantsi komthwalo othile icinezelwe kwi-Q215 edibeneyo ye-square data surface data, ngokutsho. kuxinzelelo kwinqanaba lokumisela ixabiso le-Angle.Iindlela ezimbalwa ezisetyenziswayo yi-HB, HRA, HRB, HRC kunye ne-HV.Iplastiki ye-angular ibhekisela kumandla edatha yesinyithi phantsi komthwalo, i-deformation yeplastiki (i-deformation esisigxina) ngaphandle komonakalo.Iplastiki Q215 welded square tube non-standard ingenamthungo square tube is a ingenamthungo engqukuva extrusion ukubumba ityhubhu.Ityhubhu engenamthungo kunye namanqaku e-weld kuthetha, luhlobo lwetyhubhu yentloko yesikwere (ityhubhu ye-torque), umoya weentlobo ezininzi zezinto ezikwaziyo ukwenza umbhobho weqela (ityhubhu ye-square torque), iphakathi ukusuka, kutheni, kusetyenziswa ntoni. ngumbindi, igcuntswana elikhulu Q215 welded square tube ityhubhu yentsimbi njengeqaqobana, kuba isakhiwo ityhubhu square, ityhubhu mhlophe isikwere, umbhobho abayili (square torque ityhubhu), njl ityhubhu Intshayelelo Square tube imisebenzi.

Ukuqulunqwa kwemichiza

Izixhobo ze-S460N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ubuninzi 0.2 | ubuninzi 0.6 | 1 - 1.7 | ubuninzi 0.8 | ubuninzi 0.03 | ubuninzi 0.025 | ubuninzi 0.3 | ubuninzi 0.1 | ubuninzi 0.2 | ubuninzi 0.025 | ubuninzi 0.05 | ubuninzi 0.05 | ubuninzi 0.02 | ubuninzi 0.55 | ubuninzi 0.55 |

Izixhobo ze-S420N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ubuninzi 0.2 | ubuninzi 0.6 | 1 - 1.7 | ubuninzi 0.8 | ubuninzi 0.03 | ubuninzi 0.025 | ubuninzi 0.3 | ubuninzi 0.1 | ubuninzi 0.2 | ubuninzi 0.025 | ubuninzi 0.05 | ubuninzi 0.05 | ubuninzi 0.02 | ubuninzi 0.55 | ubuninzi 0.52 |

Isixhobo se-S420NL:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ubuninzi 0.2 | ubuninzi 0.6 | 1 - 1.7 | ubuninzi 0.8 | ubuninzi 0.025 | ubuninzi 0.02 | ubuninzi 0.3 | ubuninzi 0.1 | ubuninzi 0.2 | ubuninzi 0.025 | ubuninzi 0.05 | ubuninzi 0.05 | ubuninzi 0.02 | ubuninzi 0.55 | ubuninzi 0.52 |

Isixhobo se-S460NL:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ubuninzi 0.2 | ubuninzi 0.6 | 1 - 1.7 | ubuninzi 0.8 | ubuninzi 0.025 | ubuninzi 0.02 | ubuninzi 0.3 | ubuninzi 0.1 | ubuninzi 0.2 | ubuninzi 0.025 | ubuninzi 0.05 | ubuninzi 0.05 | ubuninzi 0.02 | ubuninzi 0.55 | ubuninzi 0.55 |

Iipropati zoomatshini

Izixhobo ze-S460N

| Ubukhulu begama (mm): | ukuya kwi-100 | 100 - 200 |

| RmAmandla okuqina (MPa) | 540-720 | 530-710 |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 |

| ReH-Amandla esivuno esincinci (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Amandla empembelelo (J) ubude., (+N) | +20 ° 55 | 0 ° 47 | -10 ° 43 | -20 ° 40 | |

| KV- Amandla empembelelo (J) anqamlezileyo, (+N) | +20 ° 31 | 0 ° 27 | -10 ° 24 | -20 ° 20 | |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 |

| A- Min.elongation Lo = 5,65 √ Ke (%) | 17 | 17 | 17 | 17 | 17 |

Isixhobo se-S420N:

| Ubukhulu begama (mm): | ukuya kwi-100 | 100 - 200 | 200 - 250 |

| RmAmandla okuqina (MPa) | 520-680 | 500-650 | 500-650 |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 | 200 - 250 |

| ReH-Amandla esivuno esincinci (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Amandla empembelelo (J) ubude., (+N) | +20 ° 55 | 0 ° 47 | -10 ° 43 | -20 ° 40 | |

| KV- Amandla empembelelo (J) anqamlezileyo, (+N) | +20 ° 31 | 0 ° 27 | -10 ° 24 | -20 ° 20 | |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 | 200 - 250 |

| A- Min.elongation Lo = 5,65 √ Ke (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Isixhobo se-S420NL:

| Ubukhulu begama (mm): | ukuya kwi-100 | 100 - 200 | 200 - 250 |

| RmAmandla okuqina (MPa) | 520-680 | 500-650 | 500-650 |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 | 200 - 250 |

| ReH-Amandla esivuno esincinci (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Amandla empembelelo (J) ubude., (+N) | +20 ° 63 | 0 ° 55 | -10 ° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Amandla empembelelo (J) anqamlezileyo, (+N) | +20 ° 40 | 0 ° 34 | -10 ° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 | 200 - 250 |

| A- Min.elongation Lo = 5,65 √ Ke (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Isixhobo se-S460NL:

| Ubukhulu begama (mm): | ukuya kwi-100 | 100 - 200 |

| RmAmandla okuqina (MPa) | 540-720 | 530-710 |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 |

| ReH-Amandla esivuno esincinci (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Amandla empembelelo (J) ubude., (+N) | +20 ° 63 | 0 ° 55 | -10 ° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Amandla empembelelo (J) anqamlezileyo, (+N) | +20 ° 40 | 0 ° 34 | -10 ° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Ubukhulu begama (mm): | ukuya ku16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 |

| A- Min.elongation Lo = 5,65 √ Ke (%) | 17 | 17 | 17 | 17 | 17 |

Umboniso weMveliso