Intsimbi ye-L485 yombhobho yoshishino lwepetroleum

I-L485 Pipeline Steel, Ibhekisa kuhlobo lwentsimbi eneemfuno ezizodwa ezisetyenziselwa ukuhambisa ioyile, igesi yendalo kunye neminye imibhobho.Ngokobunzima kunye nokwakheka okulandelayo kunye neminye imiba, inokuveliswa ngelitye lokusila elishushu, ilitye lokusila okanye i-plate mill, kwaye yenziwe nge-spiral welding okanye i-UOE ethe ngqo yomthungo welding yombhobho omkhulu wentsimbi.

Intsimbi yePipeline L485, intshayelelo kwi

Uthutho lwemibhobho nothutho lukaloliwe, uthutho lohola wendlela, uthutho lwamanzi kunye nothutho ngenqwelomoya zidweliswe njengeendlela ezintlanu zothutho zale mihla.Ukusukela kumbhobho wokuqala wemizi-mveliso ukuza kuthi ga ngoku, ulwakhiwo lwemibhobho ye-oyile nerhasi lufumene malunga neenkulungwane ezimbini zophuhliso.Ukuveliswa kunye nokusetyenziswa kwentsimbi yombhobho kwaqala emva kwexesha eChina, kwaye kwakungekho mveliso yentsimbi yokwenene yombhobho ngaphambi kowe-1985. Nangona kunjalo, kwiminyaka yamuva nje, uphuhliso, uphuhliso kunye nokusetyenziswa kwentsimbi yombhobho e-China kuye kwaphuhliswa ngokukhawuleza.Ngokukhuthazwa kweeprojekthi ezinkulu zemibhobho efana nombhobho wentshona, umbhobho wothumelo lwerhasi eNtshona-mpuma kunye nombhobho womgca wesibini wokuhanjiswa kwerhasi entshona-mpuma, ukuveliswa kunye nokusetyenziswa kwentsimbi yombhobho yeX60, X70 kunye neX80 kugqitywe ngokulandelelana, kwaye iziphumo zophando. ye-X100 kunye ne-X120 ifunyenwe.

Intsimbi ye-L485 yePipeline, Iintlobo zeeTishu

I-L485 Pipeline Steel, Isakhiwo sombutho sisisiseko sokumisela ukusebenza kwayo kunye nenkonzo ekhuselekileyo.Okwangoku, iintsimbi zemibhobho zinokwahlulwa zibe ngamacandelo amane alandelayo ngokwe-microstructure yazo:

1. Ferritic pearlite intsimbi yombhobho

Umbhobho wentsimbi ye-ferritic pearlite sisakhiwo esisisiseko sentsimbi yombhobho eyaphuhliswa ngaphambi kweminyaka yee-1960.I-X52 kunye nentsimbi yombhobho enomgangatho wamandla asezantsi zonke ziyiperitic pearlite.Amacandelo ayo asisiseko yikhabhoni kunye ne-manganese, kunye nomxholo wekhabhoni (i-fraction mass, efanayo ngezantsi) yi-0.10% ukuya kwi-0.20%, kwaye umxholo we-manganese ngu-1.30% ukuya kwi-1.70%.Ngokuqhelekileyo sebenzisa i-hot rolling okanye imveliso yenkqubo yonyango eshushu.Xa kufuneka amandla aphezulu, umda ophezulu womxholo wekhabhoni unqweneleka, okanye ulandele i-niobium kunye ne-vanadium yongezwa kwinkqubo ye-manganese.Iintsimbi zemibhobho ye-pearlite ye-Ferritic zithathwa njenge-polygonal ferrite kunye nobukhulu obuziinkozo malunga ne-7μm kunye ne-pearlite eneqhezu lomthamo malunga ne-30%.Iintsimbi eziqhelekileyo zombhobho we-ferritic pearlite yi-5LB, X42, X52, X60, X60 kunye ne-X70.

2. Intsimbi yombhobho we-acicular ferrite

Uphando lwentsimbi yombhobho we-acicular ferritic lwaqala ngasekupheleni kweminyaka yee-1960 kwaye lwafakwa kwimveliso yemizi-mveliso ekuqaleni koo-1970.Ngelo xesha, i-manganese - inkqubo ye-niobium esekelwe ku-E yavelisa i-carbon ephantsi.Kwi-mn-Mo-Nb yentsimbi yombhobho we-microalloy, ukongezwa kwe-molybdenum kunokunciphisa ubushushu benguqu ukunqanda ukubunjwa kwe-polygonal ferrite, ukukhuthaza ukuguqulwa kwe-acicular ferrite, kunye nokuphucula impembelelo yokuqinisa imvula yekhabhoni kunye ne-niobium nitride, ukuze kwandiswe amandla entsimbi. kunye nokunciphisa ukuqina kunye ne-brittle-transition yeqondo lokushisa.Le teknoloji ye-molybdenum alloying sele ikwimveliso phantse iminyaka engama-40.Kwiminyaka yakutshanje, enye itekhnoloji yobushushu obuphezulu bokufumana i-acicular ferrite iyavela.Inokufumana i-acicular ferrite kwiqondo lokushisa eliphezulu lokuqengqeleka ngokusebenzisa iteknoloji ephezulu ye-niobium alloying.Iintsimbi eziqhelekileyo ze-acicular ferrite pipeline ziyi-X70 kunye ne-X80.

3. I-Bainite - intsimbi yombhobho we-martensite

Ngophuhliso loxinzelelo oluphezulu kunye nokuhamba okukhulu kombhobho wegesi yendalo yentsimbi kunye nokufuna ukunciphisa iindleko zokwakhiwa kwemibhobho, isakhiwo se-acicular ferrite asikwazi ukuhlangabezana neemfuno.Ngasekupheleni kwenkulungwane yama-20, kwavela uhlobo lwentsimbi yombhobho eyomelela kakhulu.Amanqanaba entsimbi aqhelekileyo yi-X100 kunye ne-X120.I-X100 yaxelwa okokuqala yi-SMI eJapan ngo-1988. Emva kweminyaka yophando kunye nophuhliso, umbhobho we-X100 waqala ukubekwa kwicandelo lovavanyo lobunjineli ngo-2002. Ngo-1996, isebenzisana ne-SMI kunye ne-NSC yaseJapan ukukhuthaza ngokudibeneyo inkqubo yophando ye-X120.Ngo-2004, intsimbi ye-X120 yabekwa okokuqala kwicandelo lokulinga lombhobho.

Kuyilo lokuqulunqwa kwentsimbi yombhobho we-bainite-martensitic, eyona ndibaniselwano yekhabhoni-manganese-ibhedu-nikeli-nickel-molybdenum-niobium-vanadium-titanium-boron ikhethiwe.Uyilo lwale alloy lusebenzisa ngokupheleleyo iimpawu ezibalulekileyo ze-boron kwi-dynamic transition dynamics.Ukongezwa kwe-trace boron (ωB=0.0005% ~ 0.003%) kunokunqanda ngokucacileyo i-nucleation ye-ferrite kumda weenkozo ze-austenite kwaye yenze ijika le-ferrite litshintshele ngasekunene ngokucacileyo.Nakwi-ultra-low carbon (ωC=0.003%), i Ijiko lenguqu ye-bainite yenziwe mcaba ngokwehlisa ubushushu bokugqibela bokupholisa (& LT; 300℃) kunye nezinga lokupholisa eliphuculweyo (> 20℃/s), i-bainite esezantsi kunye nesakhiwo se-lath martensite sinokufumaneka.Iintsimbi eziqhelekileyo ze-bainite-martensite (B -- M) yi-X100 kunye ne-X120.

4. Intsimbi yombhobho yesophorite epholileyo

Ngophuhliso loluntu, insimbi yombhobho iyadingeka ukuba ibe namandla aphezulu kunye nokuqina.Ukuba itekhnoloji elawulwayo yokuqengqeleka kunye nokupholisa ayinakuhlangabezana neemfuno ezinjalo, inkqubo yonyango lobushushu lokucinywa okuqinileyo kunye nokufudumeza inokwamkelwa ukuhlangabezana neemfuno ezibanzi zodonga olungqingqwa, amandla aphezulu kunye nokuqina okwaneleyo ngokwenza i-sorbitite enomsindo.Kwimibhobho yentsimbi, le sortensite yehomogenous, ekwabizwa ngokuba yihomogenous martensite, luhlobo lombutho lwentsimbi yombhobho wentsimbi X120.

Ukuqulunqwa kwemichiza

I-L245 Pipeline Steel, Ubunzima bokubala ifomula :[(idayamitha yangaphandle - ubukhulu bodonga)* ubukhulu bodonga]*0.02466=kg/m (ubunzima ngemitha nganye)

| Ukwakhiwa kwemichiza (iqhezu lobunzima)…/% | icarbon equivalent(CEV) | |||||||||||||||||

| C | Si | Mn | P | S | Nb | V | Ti | Cr | Ni | Cu | N | Mo | B | Als | ||||

| ngaphantsi okanye ukulingana |

| ngaphantsi okanye ukulingana | ||||||||||||||||

| Q345 | A | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 |

|

|

| 0.3 | 0.5 | 0.2 | 0.012 | 0.1 |

|

| 0.45 | |

| B | 0.035 | 0.035 |

|

|

|

|

| |||||||||||

| C | 0.03 | 0.03 | 0.07 | 0.15 | 0.2 |

| 0.015 | |||||||||||

| D | 0.18 | 0.03 | 0.025 |

| ||||||||||||||

| E | 0.025 | 0.02 |

| |||||||||||||||

| Q390 | A | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.07 | 0.2 | 0.2 | 0.3 | 0.5 | 0.2 | 0.015 | 0.1 |

|

| 0.46 | |

| B | 0.035 | 0.035 |

|

| ||||||||||||||

| C | 0.03 | 0.03 |

| 0.015 | ||||||||||||||

| D | 0.03 | 0.025 |

| |||||||||||||||

| E | 0.025 | 0.02 |

| |||||||||||||||

| Q420 | A | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.07 | 0.2 | 0.2 | 0.3 | 0.8 | 0.2 | 0.015 | 0.2 |

|

| 0.48 | |

| B | 0.035 | 0.035 |

| 0.015 | ||||||||||||||

| C | 0.03 | 0.03 |

| |||||||||||||||

| D | 0.03 | 0.025 |

| |||||||||||||||

| E | 25 | 0.02 |

| |||||||||||||||

| Q450 | C | 0.2 | 0.6 | 1.8 | 0.03 | 0.03 | 0.11 | 0.2 | 0.2 | 0.3 | 0.8 | 0.2 | 0.015 | 0.2 | 0.005 | 0.015 | 0.53 | |

| D | 0.03 | 0.025 | ||||||||||||||||

| E | 0.025 | 0.02 | ||||||||||||||||

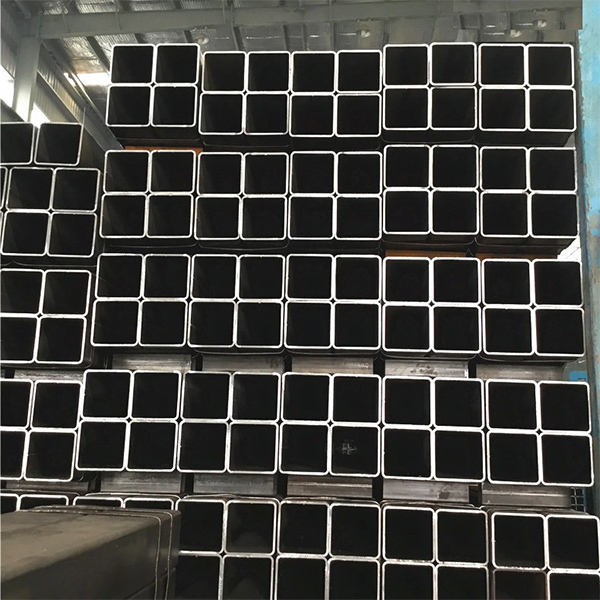

Umboniso weMveliso