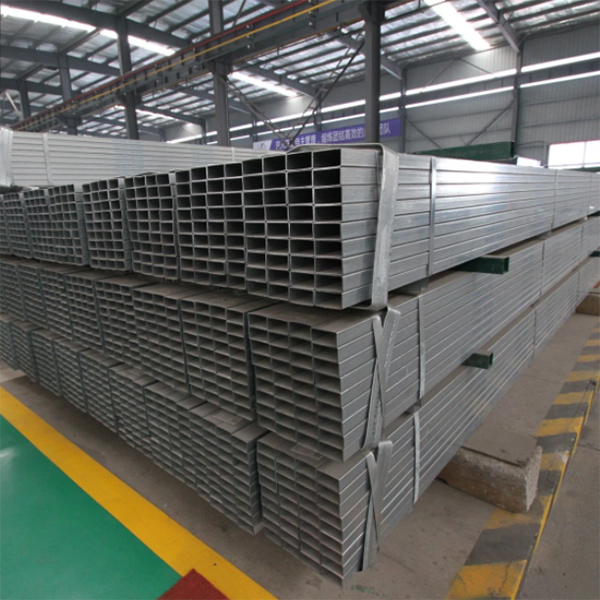

I-ASTM A500 yesikwere sentsimbi yombhobho womthengisi indawo

I-A500 Carbon Steel Square Tubing, umbhobho omkhulu wentsimbi yesikwere, umbhobho wentsimbi ongenamthungo, umbhobho wentsimbi ophantsi, 135 * 135 * 10 umbhobho wentsimbi yesikwere, umbhobho wentsimbi yesikwere senqaba, Q345B umbhobho wentsimbi osezantsi, 20 # intsimbi engenamthungo. umbhobho

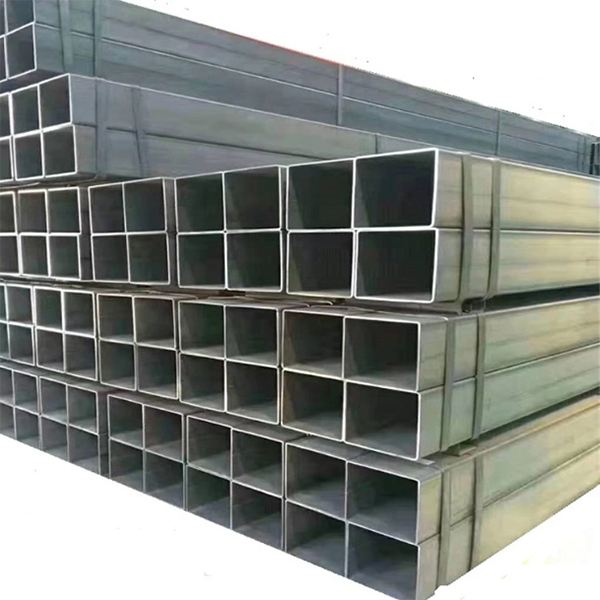

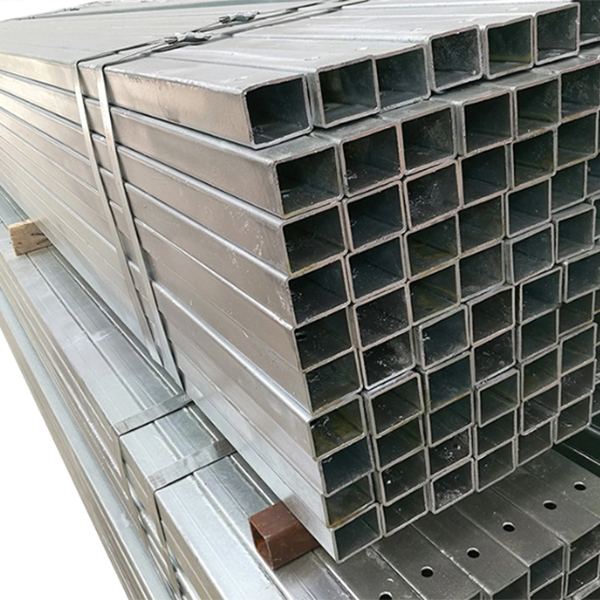

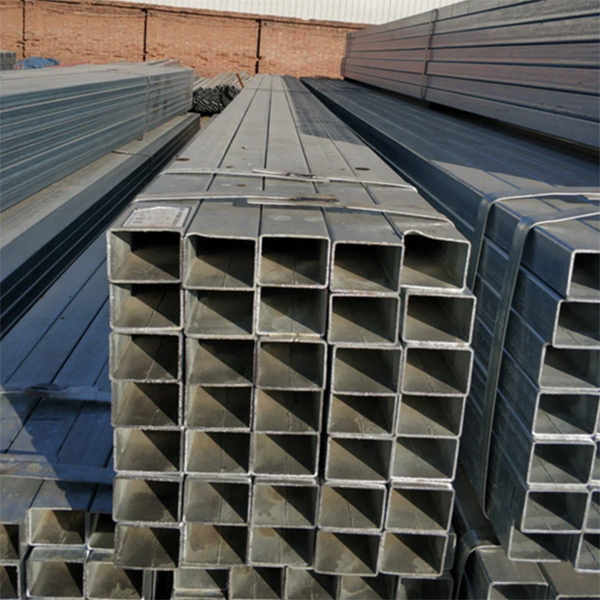

I-A500 Carbon Steel Square Tubing, njengoko negama lisitsho, iyimilo yesikweri yetyhubhu, iintlobo ezininzi zezinto ezinokuthi zenze i-square tube body, i-medium yayo, into enokusetyenziswa, apho isetyenziselwa khona, uninzi lombhobho wesquare ukuya kwintsimbi. umbhobho ngenxa yesininzi, ubukhulu becala kumbhobho wesikwere wolwakhiwo, umbhobho wokuhombisa isikwere, umbhobho wokwakha wesikwere njalo njalo.

Umbhobho wesikwere ligama lombhobho wesikwere, oko kukuthi, umbhobho wentsimbi onobude obulinganayo kumacala omabini.Yenziwe ngentsimbi yentsimbi emva kokucubungula kunye nokuqengqeleka.Ngokuqhelekileyo, i-strip ikhutshwe, ihlanjululwe, ikhutshwe kwaye ifakwe kwi-tube ejikelezayo, ehlanganiswe kwityhubhu yesikwere kwaye inqunyulwe ubude obufunekayo.Ngokwesiqhelo iinkuni ezingama-50 ngepakethe nganye.

Ulwahlulo kunye neNtsebenzo

I-A500 yeCarbon Steel Square Tubing engenamthungo yahlulwe yaba yi-seamless kunye ne-weld, umbhobho osikwere ongenamthungo wenziwa nge-extrusion yetyhubhu ejikelezayo engenamthungo.Umbhobho wentsimbi yesikwere, udonga olungqingqwa lombhobho wentsimbi, umbhobho omkhulu wentsimbi, umbhobho wentsimbi ongenamthungo, umbhobho wentsimbi osezantsi, 135 * 135 * 10 umbhobho wentsimbi yesikwere, umbhobho wentsimbi yesikwere, Q345B umbhobho wentsimbi osezantsi, Q345B # umbhobho wentsimbi ongenamthungo

1. Uhlalutyo lwesalathisi sokusebenza kwetyhubhu yensimbi yesikwere - iplastiki

I-Plastiki ibhekisela kwikhono lezinto zetsimbi ukuvelisa i-deformation yeplastiki (i-deformation esisigxina) ngaphandle komonakalo phantsi komthwalo.

2. Uhlalutyo lwesalathisi sokusebenza kwetyhubhu yensimbi yesikwere - ukuqina

Ukuqina yigeyiji yokuba ukuqina okanye ukuthamba kwesixhobo sentsimbi.Okwangoku, eyona ndlela isetyenziswa ngokuqhelekileyo ukufumanisa ubulukhuni kwimveliso yindlela yokuqina kwe-indenter, leyo kukusebenzisa imilo ethile yejometri yentloko ye-indenter phantsi komthwalo othile kumphezulu wezinto ezivavanyiweyo zetsimbi, ngokwenqanaba indenter ukumisela ixabiso lobulukhuni bayo.

Iindlela ezisetyenziswa ngokuqhelekileyo ziiBrinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) kunye neVickers hardness (HV) kunye nezinye iindlela.

3. Uhlalutyo lwesalathisi sokusebenza kwetyhubhu yensimbi yesikwere - ukukhathala

Amandla, iplastiki, kunye nokuqina okuxoxwe ngasentla zizibonakaliso zeempawu zomatshini wesinyithi phantsi kokulayisha okumileyo.Enyanisweni, iindawo ezininzi zoomatshini zisebenza phantsi kwemithwalo ye-cyclic, kwaye ukukhathala kunokwenzeka phantsi kwezi meko.

4. Uhlalutyo lwesalathisi sokusebenza kombhobho wensimbi yesikwere - ukuqina kwempembelelo

Umthwalo osebenza kwiindawo ngesantya esiphezulu ubizwa ngokuba ngumthwalo wempembelelo, kwaye ukukwazi kwesinyithi ukuxhathisa umonakalo phantsi komthwalo wempembelelo kubizwa ngokuba yimpembelelo yokuqina.

5. Uhlalutyo lwesalathiso sokusebenza kwetyhubhu yentsimbi yesikweri - ityhubhu yentsimbi yesikwere, ityhubhu yentsimbi engqindilili yodonga, ityhubhu yentsimbi ebanzi ububanzi, iityhubhu yentsimbi engenamthungo, ityhubhu yentsimbi ephantsi, 135 * 135 * 10 ityhubhu yentsimbi yesikwere ityhubhu yentsimbi, i-Q345B ephantsi ye-alloy square tube, i-20 # i-square yentsimbi engenamthungo

Amandla amandla ezinto zetsimbi ukuxhathisa ukungaphumeleli (i-deformation yeplastiki egqithisileyo okanye i-fracture) phantsi kokulayisha i-static.Ngenxa yendlela yokulayisha ngendlela yokwelula, ukunyanzeliswa, ukugoba, ukucheba, ngoko ke amandla ahlulahlulwe abe ngamandla okuqina, amandla oxinzelelo, amandla okugoba, amandla okucheba njalo njalo.Kuhlala kukho unxibelelwano oluthile phakathi kwamandla ahlukeneyo, kwaye amandla okuqina asetyenziswa ngokubanzi njengesona salathisi samandla esisisiseko.

Phelisa imilo:isiphelo esityebileyo, isiphelo esisicaba, shwaka okanye ukongeza isigqubuthelo seplastiki ukukhusela iziphelo ngokweemfuno zomthengi.

Itekhnoloji:ukuqengqeleka okushushu, ukuqengqeleka okubandayo

A500 Carbon Steel Square Tubing Isicelo

1. Ukusetyenziswa kwezakhiwo, ukwakhiwa kwemizi-mveliso kunye neendawo zokuhlala

2. Ipali yocingo / ucingo / iibholadi / ibhedi

3. Irhasi

4. Kwinkqubo yokutshiza umlilo/unikezelo lwamanzi

5. Izixhobo zezemidlalo/ipali yokukhanya/isibane

6. Ezolimo/indlu eluhlaza

Inkcazo

| Ukumelana ne-welding | |||||||||

| into | Ubuninzi bokwakheka kweekhemikhali % | into | Indlela yokuziphatha koomatshini | ||||||

| intsimbi | C% | IManganese % | % | % | isilicon% | intsimbi | Inqaku lesivuno uMpa | Amandla okuqina uMpa | Elongation |

| Iklasi A | 0.25 | 0.95 | 0.045 | 0.05 | -- | Iklasi A | 205 (imizuzu) | 330 (imizuzu) | 26-30 |

| Udidi B | 0.3 | 1.2 | 0.045 | 0.05 | -- | Udidi B | 240 (imizuzu) | 415 (imizuzu) | 21-26 |

| ImiGangatho yoMgangatho: I-ASTM A53 i-ASTM A500 iNkcazo eMigangatho yoMbhobho, iDiphu emnyama kunye neHot, iGalvanized, iWelded, kunye neTubing engenamthungo | |||||||||

Ukuqulunqwa kwemichiza

| Iimfuno zemichiza | Indlela yokuziphatha koomatshini | ityhubhu yesakhiwo esikhethekileyo | |||||||||

| Isiqalelo | umsebenzi.% | Iklasi A | Udidi B | Udidi C | Udidi D | ||||||

| Udidi A, B, D | Udidi C | Amandla okuqina, min, | psi | 45000 | 58000 | 62000 | 58000 | ||||

| Thermal Uhlalutyo | Imveliso Uhlalutyo | Thermal Uhlalutyo | Imveliso Uhlalutyo | MPa | 310 | 400 | 427 | 400 | |||

| Isivuno Amandla, Min, | psi | 33000 | 42000 | 46000 | 36000 | ||||||

| C, ubuninzi | 0.26 | 0.30 | 0.23 | 0.27 | MPa | 228 | 290 | 317 | 250 | ||

| IManganese, ubuninzi | … | … | 1.35 | 1.40 | 2" ubude.(50.8mm), umz% | 25 | amashumi amabini anantathu | amashumi amabini ananye | amashumi amabini anantathu | ||

| P, ubuninzi | 0.035 | 0.045 | 0.035 | 0.045 | UMgangatho woMgangatho: i-ASTM A500 iNgcaciso eMiselweyo yoMjikelo oMjikelo kunye neMilo eNkunkqele eFakelwe i-Welded kunye ne-Seamless Carbon Steel Structural Pipe | ||||||

| encinci, inkulu | 0.035 | 0.045 | 0.035 | 0.045 | |||||||

| Ubhedu, (xa kucacisiwe) min. | 0.20 | 0.18 | 0.20 | 0.18 | |||||||

Umboniso weMveliso