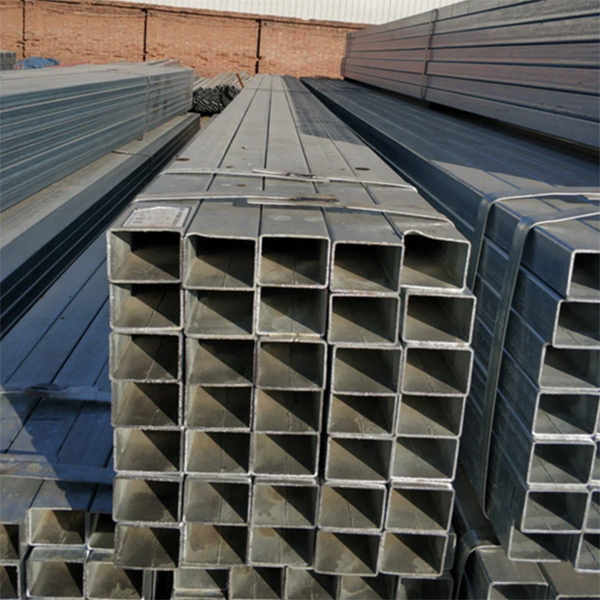

I-alloy Square Rectangular Tube

Ingxubevange yesikwere ityhubhu yoxande Ikwabizwa ngokuba sisikwere kunye noxande ukubanda kwakhiwe intsimbi ekroliweyo, ekubhekiselwa kuyo njengombhobho osisikwere kunye nombhobho oxande, ikhowudi F kunye noJ ngokulandelelanayo.

1. Ingxubevange yesikwere ityhubhu yoxande Ukutenxa okuvumelekileyo kobukhulu bodonga akusayi kudlula okulungileyo okanye okubi kwi-10% yobukhulu bodonga lwegama xa ubukhulu bodonga bungaphantsi kwe-10mm, kunye ne-8% ye-8% yobukhulu bodonga xa udonga ngaphezu kwe-10mm, ngaphandle kobunzima bodonga lwekona kunye nendawo ye-weld.

2. I-alloy square tube i-rectangular Ngokuqhelekileyo ubude bokuhanjiswa buyi-4000mm-12000mm, kunye ne-6000mm kunye ne-12000mm kuninzi.Ityhubhu ye-square ye-rectangular ivumela ukuhanjiswa kwemveliso engekho ngaphantsi kwe-2000mm emfutshane kunye neemveliso ezingaqhelekanga, nazo zinokuhanjiswa ngendlela ye-tube yojongano, kodwa umthengi kufuneka asuse ityhubhu yojongano xa usebenzisa.Ubunzima beemveliso ezimfutshane kunye nezingaqhelekanga aziyi kudlula i-5% yomthamo opheleleyo wokuhanjiswa, kunye neetyhubhu ezisikwere ezinoxande ezinobunzima obungaphezulu kwe-20kg/m aziyi kudlula i-10% yobuninzi bokuhanjiswa.

3. I-alloy square tube i-rectangular tube Ukugoba akufanele kube mkhulu kune-2mm ngemitha nganye kwaye ukugoba okupheleleyo akufanele kube ngaphezu kwe-0.2% yobude obupheleleyo.

4. Ingxubevange ityhubhu square uxande Ngokwenkqubo yemveliso: ityhubhu eshushu yaqengqeleka ingenamthungo square, ityhubhu ebandayo itsalwa ingenamthungo square, cudiza ingenamthungo square tube, welded square tube.

Umbhobho wesquare odibeneyo uhlukaniswe

1, ngokwenkqubo: i-arc welding square tube, ukumelana ne-welding square tube (i-frequency ephezulu, i-frequency ephantsi), i-gas welding square tube, ityhubhu ye-welding square.

2, ngokwe-weld - umthungo othe tye we welding square pipe, i-spiral welding square pipe.

I-alloy Square Rectangular Tube Ukuhlelwa kwezinto

Ityhubhu yesikwere ngokwezinto eziphathekayo: ityhubhu ye-carbon steel square, i-alloy ephantsi yesikwere ityhubhu.

1, carbon steel jikelele yahlulwe: Q195, Q215, Q235, SS400, 20 # intsimbi, 45 # intsimbi njalo njalo.

I-2, intsimbi ephantsi ye-alloy ihlukaniswe: Q345, 16Mn, Q390, ST52-3, njl.

Ukuhlelwa koMgangatho weMveliso

Ityhubhu yesikwere ngokwemigangatho yemveliso: ityhubhu yesikwere se-gb, ityhubhu yesikwere saseJapan esiqhelekileyo, ityhubhu yesikwere yenkqubo yaseBritani, ityhubhu enesikweri esiqhelekileyo saseMelika, ityhubhu yesikwere esiqhelekileyo saseYurophu, ityhubhu yesikwere esingeyomgangatho.

Ulwahlulo lweMilo yeCandelo

Imibhobho yesikwere ihlelwa ngokwemilo yecandelo:

I-1, icandelo elilula letyhubhu yesikwere: ityhubhu yesikwere, i-rectangular square tube.

2, ityhubhu yesikwere yecandelo elintsonkothileyo: ityhubhu emile okweentyatyambo, ityhubhu evulekileyo yesikwere, ityhubhu yesikwere edibeneyo, ityhubhu yesikwere emile.

Inkcazo

| Ukugqitywa komphezulu | Iimpawu kunye nesicelo |

| NO.1 | Umphezulu oqengqelekayo oshushu, oqhotyoshiweyo kunye nocoliweyo, unokusetyenziswa njengezinto eziqengqelekayo ezibandayo, iitanki zamashishini kunye nezixhobo ze-chem i cal. |

| NO.2D | I-cold-rolled, ivalwe kunye nepiki ekhokelwa ngaphandle kokudlula eluswini i-ucts ebuthuntu yemveliso inokusetyenziswa njengamalungu e-auto mo bile, ukwakha izixhobo kunye nemibhobho. |

| NO.2B | Ukuqaqamba komphezulu kunye nokuthe tyaba kwe-NO.2B kungcono kuno-NO.2D.Emva koko ngokusebenzisa umphezulu okhethekileyo wokuphucula iipropathi zayo zoomatshini, i-N02B ingaphantse yanelise ukusetyenziswa kwangaphambili. |

| NO.3 | Igudiswe ngebhanti erhabaxa yegrit #100#120,ibenokukhanya okubhetele ngakumbi kunye ne-dis con tin uous coarse stria, esetyenziswa njengangaphakathi nangaphandle okanye izinto zokwakha, i-electri cal appli anc es nasekhitshini sil njl. |

| NO.4 | Ikhazimliswe ngebhanti erhawukileyo yegrit #150#180, inokukhanya okungcono kunye ne-discontinuous coarse stria, kodwa ibhityile kune-NO.3, isetyenziswa njengebhafu yesakhiwo sangaphakathi kunye nezihombiso zangaphandle izixhobo zombane, izixhobo zasekhitshini kunye nezixhobo zokulungisa ukutya njl.njl. |

| HL | Ipholishelwe ngebhanti elirhabaxa legrit #150-320 kwiNombolo ye-4 kwaye inemizila eqhubekayo, esetyenziswa ikakhulu njengezinto zokuhombisa zokwakha, ii-elevators, umnyango wesakhiwo, ipleyiti yangaphambili njl. |

| BA | Ingqele iqengqeleke, ikhazimle ivalwe kwaye ulusu ludlulile, imveliso igqwese ngokuqaqamba kunye nokuguquguquka okuhle njengesipili, esisetyenziselwa izixhobo zombane, isipili, ikhitshi yesixhobo sombane, okanye izixhobo zentengiso njl.njl. |

Iphepha leDatha leBanga lombhobho

| Ingxubevange | UNS | Inkcazo |

| 304/304L | S30400/S30403 | I-Chromium-Nickel austenitic alloy esetyenziswa kwizicelo zorhwebo. |

| 304 | S30400 | I-Chromium-Nickel austenitic alloy esetyenziswa kwizicelo zorhwebo. |

| 304L | S30403 | I-Chromium-Nickel austenitic alloy esetyenziswa kwizicelo zorhwebo. |

| 304H | S30409 | I-Chromium-Nickel austenitic alloy esetyenziswa kwizicelo zorhwebo. |

| 316/316L | S31600/S31603 | Molybdenum-ethwele iaustenitic steel stainless ekwaziyo ukumelana ngakumbi nomhlwa jikelele kunye ne-pitting / crevice corrosion. |

| 316 | S31600 | Molybdenum-ethwele iaustenitic steel stainless ekwaziyo ukumelana ngakumbi nomhlwa jikelele kunye ne-pitting / crevice corrosion. |

| 316L | S31603 | Molybdenum-ethwele iaustenitic steel stainless ekwaziyo ukumelana ngakumbi nomhlwa jikelele kunye ne-pitting / crevice corrosion. |

| 316H | S31609 | Molybdenum-ethwele iaustenitic steel stainless ekwaziyo ukumelana ngakumbi nomhlwa jikelele kunye ne-pitting / crevice corrosion. |

| 309S | S30908 | I-Austenitic steel stainless idla ngokusetyenziswa kwizicelo zobushushu obuphakamileyo. |

| 309H | S30909 | I-Austenitic steel stainless idla ngokusetyenziswa kwizicelo zobushushu obuphakamileyo. |

| 310S | S31008 | I-Austenitic steel stainless idla ngokusetyenziswa kwizicelo zobushushu obuphakamileyo. |

| 310H | S31009 | I-Austenitic steel stainless idla ngokusetyenziswa kwizicelo zobushushu obuphakamileyo. |

| 317 | S31700 | Iintsimbi ze-austenitic ezithwala i-molybdenum ezikwaziyo ukumelana nokubola ngokubanzi kunye ne-pitting / crevice corrosion kune-chromium-nickel austenitic eziqhelekileyo eziqhelekileyo. |

| 317L | S31703 | Iintsimbi ze-austenitic ezithwala i-molybdenum ezikwaziyo ukumelana nokubola ngokubanzi kunye ne-pitting / crevice corrosion kune-chromium-nickel austenitic eziqhelekileyo eziqhelekileyo. |

| 317LMN | S31726 | I-austenitic ngokupheleleyo, i-nitrogen-bearing, i-high-molybdenum insimbi engenasici ukuze isetyenziswe kwiindawo eziphezulu ze-chloride. |

| 321 | S32100 | Intsimbi ezinzileyo ezinzileyo enikezela ngokuxhathisa okugqwesileyo kwi-corrosion ye-intergranular kulandela ukuvezwa kwiqondo lobushushu kwi-chromium carbide imvula ukusuka kwi-800 ukuya kwi-1500 °F. |

| 321H | S32109 | Intsimbi ezinzileyo ezinzileyo enikezela ngokuxhathisa okugqwesileyo kwi-corrosion ye-intergranular kulandela ukuvezwa kwiqondo lobushushu kwi-chromium carbide imvula ukusuka kwi-800 ukuya kwi-1500 °F. |

| 347 | S34700 | Intsimbi ezinzileyo ezinzileyo enikezela ngokuxhathisa okugqwesileyo kwi-intergranular corrosion kulandela ukuvezwa kubushushu kwi-chromium carbide imvula ukusuka kwi-800 ukuya kwi-1500 °F. |

| 347H | S34709 | Intsimbi ezinzileyo ezinzileyo enikezela ngokuxhathisa okugqwesileyo kwi-intergranular corrosion kulandela ukuvezwa kubushushu kwi-chromium carbide imvula ukusuka kwi-800 ukuya kwi-1500 °F. |

| 348 | S34800 | Intsimbi ezinzileyo ezinzileyo enikezela ngokuxhathisa okugqwesileyo kwi-intergranular corrosion kulandela ukuvezwa kubushushu kwi-chromium carbide imvula ukusuka kwi-800 ukuya kwi-1500 °F. |

| 348H | S34809 | Intsimbi ezinzileyo ezinzileyo enikezela ngokuxhathisa okugqwesileyo kwi-intergranular corrosion kulandela ukuvezwa kubushushu kwi-chromium carbide imvula ukusuka kwi-800 ukuya kwi-1500 °F. |

| AL 611 | S30601 | Ikhabhoni ephantsi, i-silicon equlathe, i-austenitic stainless steel idla ngokusetyenziswa kwishishini lemichiza. |

Umboniso weMveliso